A hunt for enzymes to revolutionise plastic recycling

To address the plastic pollution crisis, Professor David Ackerley, Director of Te Matapihipihi The Centre for Biodiscovery at Te Herenga Waka – Victoria University of Wellington will use advanced gene-hunting techniques to discover next-generation plastic-eating enzymes

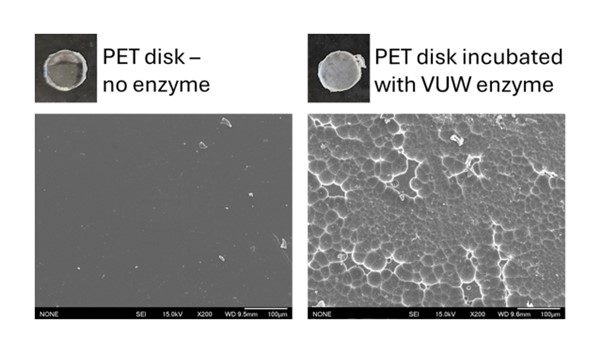

Almost all the plastic ever created still exists in the environment today. The idea of a circular economy of plastic waste, where waste is recycled back into a useful product, is gaining traction. Unfortunately, our current recycling systems are unsophisticated, producing recycled products with noticeable drops in quality and usability. A promising new process is enzymatic recycling, where enzymes break down plastic into its core components, allowing it to be remade into new, high-quality plastic.

Professor Ackerley (Ngāi Te Rangi) has received a Marsden Fund Standard grant to find the most efficient enzymes in nature and use artificial intelligence to design superior plastic-eating enzymes based on these examples. Professor Ackerley’s team has engineered common E. coli bacteria to act as microscopic detectives. These bacteria are designed to die when exposed to plastics, unless they have acquired a gene for a plastic-degrading enzyme. This allows the researchers to rapidly screen for new enzymes from DNA-rich natural sources, such as soil collected from Te Herenga Waka Marae’s new “Living Pā”, Ngā Mokopuna. This dataset of functional enzymes will then be used to train machine learning models to recognise what makes an enzyme effective at breaking down plastics.

The aim is to design a tool that can predict superior plastic-degrading enzymes from genetic databases worldwide and to position Aotearoa New Zealand at the forefront of the global bio-recycling industry.

Scanning electron micrograph image of enzyme-degraded PET plastic (image supplied)