The personal touch: Combining 3D printing and virtual reality to create objects with tactile qualities

Dr Donald Degraen from Te Whare Wānanga o Waitaha – the University of Canterbury will combine 3D printing with virtual reality to enable precise control over how objects feel, opening new possibilities for hands-on learning, professional training, and simulations

Three-dimensional (3D) printing has become ubiquitous, from model building to surgical and dental solutions. But creating 3D-printed objects with specific tactile qualities is difficult. Currently, designers are unable to predict how a printed object will feel based on its materials, structure, or surface features.

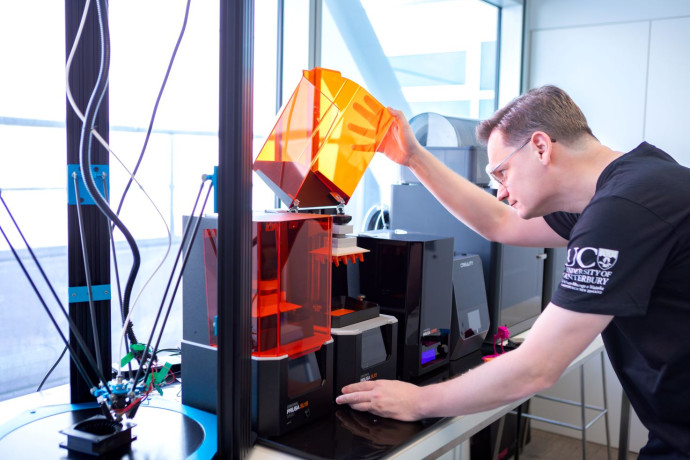

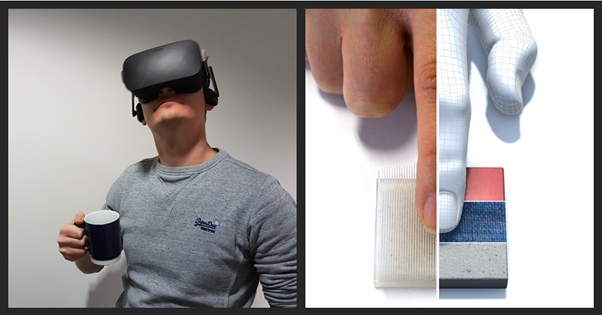

Dr Degraen, based at the Human Interface Technology Lab New Zealand (HIT Lab NZ), has been awarded a Marsden Fund Fast-Start grant to combine 3D printing with virtual reality to empower designers to craft soft, rough, smooth, or textured objects. Dr Degraen will also explore how visual cues in virtual reality can enhance or alter how we experience touch. The aim is to create design tools that allow users to define and simulate touch sensations before fabrication.

Potential applications are wide-ranging: for example, medical students could practise identifying tumours on lifelike, printed anatomical models in a virtual clinic. These tools will also lower the barrier to creating multisensory virtual reality, ultimately making virtual experiences more accessible and cost-effective. Moreover, conducting this research in Aotearoa New Zealand will build on world-leading research and expertise at the HIT Lab NZ.

Dr Degraen using a VR device; combining detailed 3D-printed objects with visual information in virtual reality creates realistic material and texture sensations (photo credits: Donald Degraen)