Research

Published 14 November 2025Magnetic marvels: Meet the multi-polar magnets

Since the discovery of the compass, magnets are indispensable in our daily lives. Yet, their fundamental characteristics have never changed; dictated by the metals they are made from. Professor Singamneni's research is about to revolutionise that.

If I had to draw a magnet, I would doodle a horseshoe-shape. Maybe with a blue and a red arm. That captures what a magnet fundamentally is: a piece of metal where one end is a magnetic south pole and the other a north pole. You cannot have one pole without the other (break a magnet and the pieces now each have two opposite poles). A magnet with three poles? I would have said that is as likely as metal that defies gravity.

The author’s idea of a magnet (illustrated by Hinrich Schaefer)

Yet, here I am at Te Wānanga Aronui o Tāmaki Makau Rau - Auckland University of Technology in Professor Sarat Singamneni’s laboratory and watch a magnetometer slide along a custom-made magnet. The readings start with positive values (a north pole) and then, as expected, change to negative numbers (a south pole). However, at the far end the readings turn positive again! In my hand, I am holding something that is not supposed to exist: a single piece of metal with three magnetic poles. It is one of a few prototypes in the world with such complex polar arrangements, all produced in this laboratory.

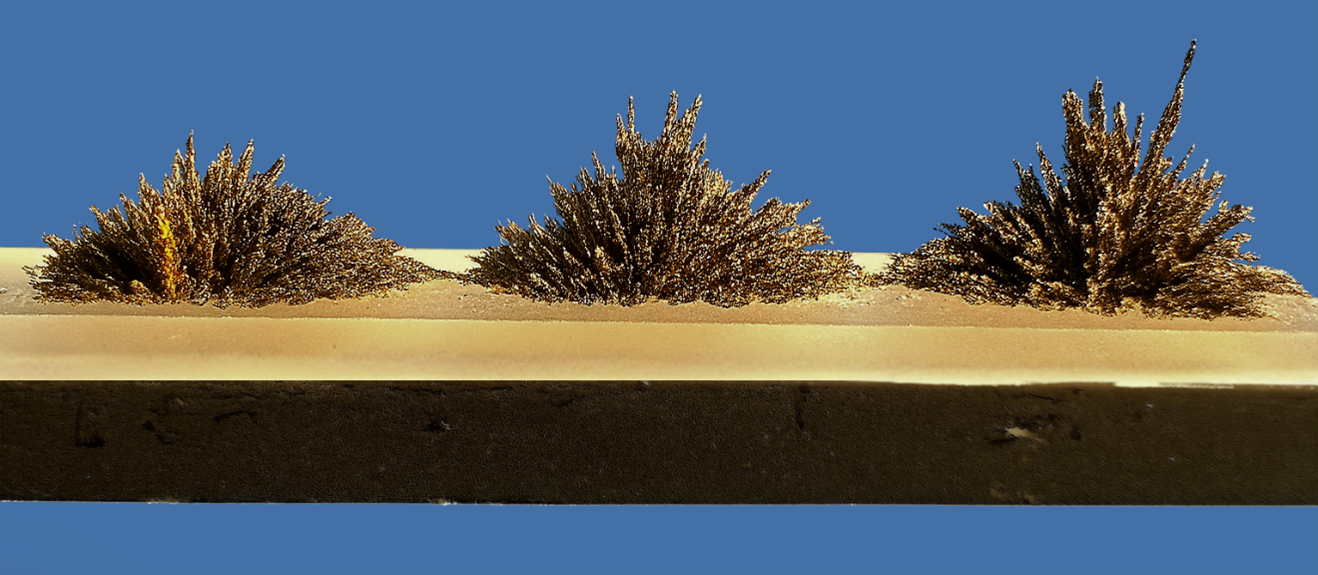

The astounding nature of these magnets can be made visible. Professor Singamneni places one with three poles on each face underneath a glass bottle in which iron particles are floating in a liquid. Each of the three poles attracts a bunch of filings and aligns them along magnetic field lines.

A three-pole magnet (black slab at bottom of the picture) deflects iron particles that are suspended in a liquid. The picture has been enhanced for clarity (photo: supplied)

To understand how multipole magnets are created, it helps to know how a conventional magnet is typically made. In any magnetic material, certain electrons spin about their axes. Each electron spin behaves like an elemental magnetic dipole. In ferromagnetic materials (like iron), these dipoles are aligned in a particular direction within a “domain”. However, each piece of material consists of multitudes of individual domains, and their external magnetic forces cancel each other out. That is, unless the material is placed in an external magnetic field. Then the dipoles across all domains become aligned in the same direction. The result is a magnet as we know it, with a north and a south pole.

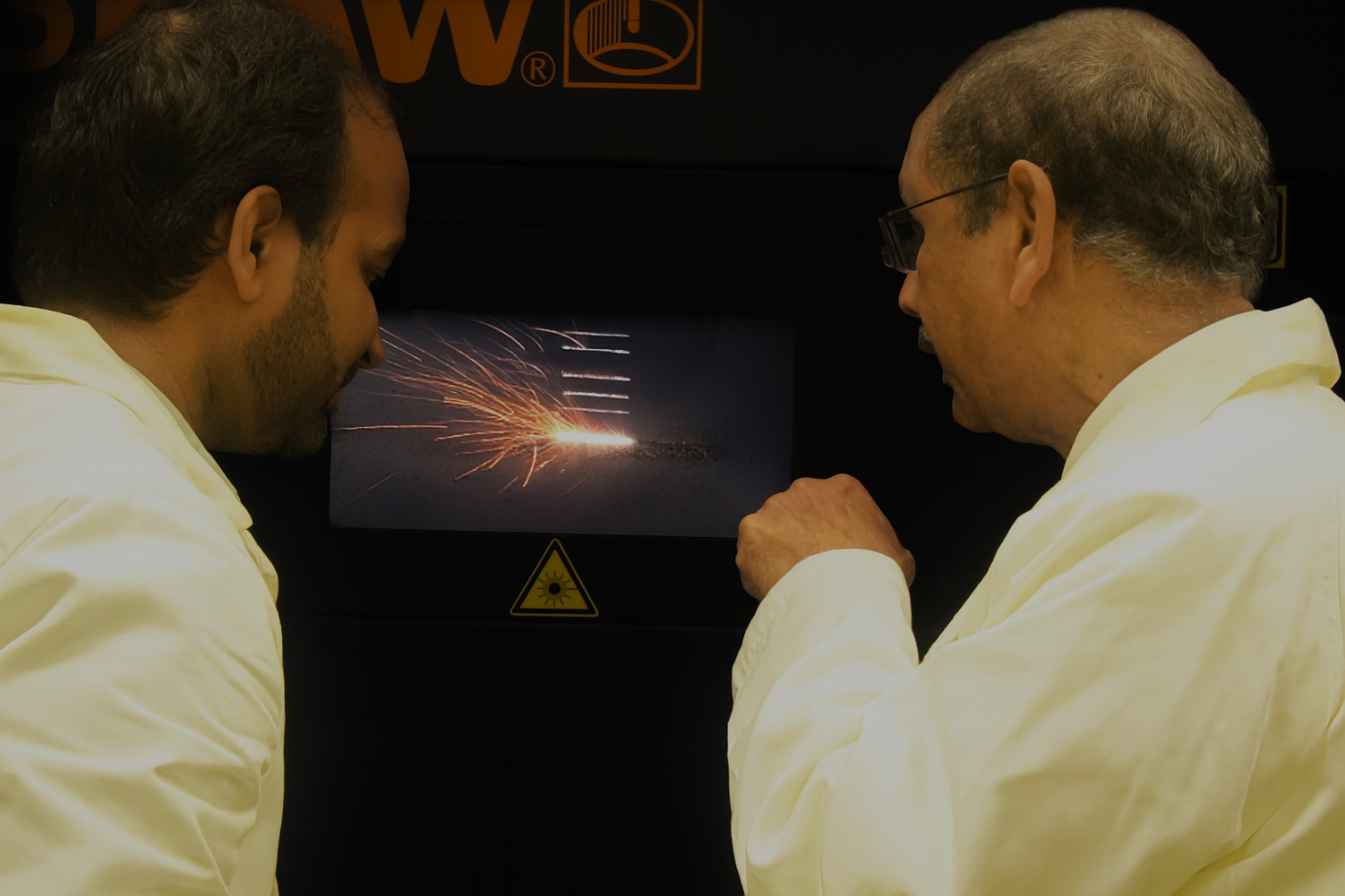

The trick that Professor Singamneni’s team developed is not to magnetise an existing piece of metal. Instead, they construct an entirely new one in a magnetic field. The process is similar to building up a brick wall. Through the window of a high precision welding (laser melting) chamber, I watch how a mechanical arm spreads out a thin, rectangular layer of magnetic metal powder. Each of these particles behaves like an individual magnet at the micro-scale. A team member switches on an external magnetic field and the particles jump as they orient themselves along the field lines. Then the swath of a laser beam scans across the powder bed. A glowing red line and a cascade of sparks indicate where the particles melt. As they cool and solidify, the elemental magnets are locked in the orientation of the external field. The foundation of the magnet is laid and then the process repeats, layer by layer, until the desired shape has formed. By applying magnetic fields with multiple reversals over the width of the magnet-to-be, the elemental magnets are forced to build the equivalent number of magnetic poles within the same piece of metal. Professor Singamneni explains that with each external pole, an opposite pole forms on the other side, thus creating dipoles. The underlying innovation lies in the clever arrangement of multiple dipole regions, by selectively varying their number, placement, and north–south orientations.

Professor Singamneni and Dr Malaya Behera monitor the laser melting chamber as a new layer is fused onto a multipolar magnet. The picture has been altered to better show the processes inside the chamber (photo: supplied)

The field is not the only thing that the team can customise to create a bespoke magnet. The shape can be adjusted by varying the footprint of the powder layers, following the principle of a 3D-printer. Using powders of different materials is yet another revolutionary innovation to build magnets that combine multiple properties. ‘Hard’ magnetic materials retain their magnetism, whereas ‘soft’ magnetic materials become magnetised under an external field but lose their magnetism once the field is removed. Each type has specific uses. By laying down multiple powdered metals with different characteristics, each in targeted regions of the magnet, Professor Singamneni is able to create the first multi-material magnets. These combine both hard and soft magnetic properties in distinct areas as required.

The prototypes so far are limited in size, strength, and shape, constrained by the set-up used currently at AUT. After all, this is a make-shift experimental system designed for a laboratory and not an industrial facility. Nonetheless, the specimens are a revelation about novel magnets and many industries are bound to take notice. Magnets are essential in all sorts of products and machinery. No electric motor can run without them. Professor Singamneni envisages whole new motor designs powered by magnets with novel and bespoke shapes and properties. The future possibilities are a fascinating perspective. Yet I also still feel the wonder of seeing something that was not expected to be. Maybe I should ask the team to make me a three-prongued horseshoe, so that it truly sinks in.

Written by Hinrich Schaefer (Kaiarotake Rangahau Research Assessor at the Royal Society Te Apārangi).

RESEARCHER

Professor Sarat Singamneni

ORGANISATION

Te Wānanga Aronui o Tāmaki Makau Rau - Auckland University of Technology

FUNDING SUPPORT

Marsden Fund

CONTRACT OR PROJECT ID

AUT1901